The glass

We must invent and learn at the same time.

Viraver designs, develops and manufactures flat or curved glass sheets, laminated security glass and other bespoke glass products tailored to the Nautical, Automotive, Architecture, Industrial and Armoured sectors.

For each sector and circumstance, Viraver contextualizes its products with particular attention to norms, regulations, and individual specifications. The company’s innovative solutions come as the design trend is heading towards ever larger glass applications. Viraver’s unique specialty is to deliver these large sizes using thinner sheets of glass, for a consequent weight reduction, but with no loss of resistance or structural quality.

Process

SAG Bending

Viraver uses the sag bending technique to create large curved surfaces. With this technology, even very thick sheets of glass can be bent, to form cylindrical and spherical curves, while retaining excellent optical properties and creating surfaces free of flaws, distortions and undulations. The experience acquired in obtaining curvature, and using the 3D processing technique for surface detection, allows the team to guarantee the continuity of the surfaces even in the most complex projects. Viraver’s larger new furnaces are able to bend glass sheets as large as 21.32ftx10.17ft (6,50mx3,10m).

Chemically Strengthened

The chemical strengthening process of glass is used to improve the physical characteristics of glass, increasing its resistance to mechanical stresses and to thermal shocks. The chemical strengthening process by its nature does not involve any kind of optical distortion and imprint on the treated glass. The chemically strengthened glass is not subject to the risk of spontaneous rupture from inclusions of Nickel Sulphide and therefore does not require Heat Soak tests. Viraver is able to produce chemically strengthened glass sheets as large as 26.4ftx10.53ft (8mx3,21m).

Silkscreen printing

Silkscreen printing is a glass printing technique which serves both aesthetic and functional purposes, as it helps to safeguard the quality of the gluing. It is achieved by printingon glass or plastic interlayer, with the use of silkscreen printing frames and suitable ink of compact and shaded bands.

Clean Room Assembly

Laminated glass is one of the most used products in projects where glass is a structural part because it combines transparency with the robustness and security features required by standards and norms. In Viraver lamination is executed for each piece of glass by bag technique and autoclave cycle. The stratification techniques used in Viraver allows innumerable materials to be added to the plastic interlayer that further enhance the purpose to the glass, for example: heating elements, heat shields, electromagnetic radiation shields, electric and decorative opacifier films.

Autoclave Lamination

This is the process in which the union between the glass and the plastic material that make up the stratified takes place. In Viraver lamination is carried out in an autoclave, which consists in subjecting the laminate to the simultaneous action of pressure, temperature and vacuum in order to generate the intimate union of the different materials. Viraver is equipped with a large new autoclave for glass and polycarbonate sheets equal to 29.53ftx10.83ft (9mx3,30m) in addition to the pre-existing one.

Final Testing

Viraver has an ISO 9001: 2015 certified quality management system. Viraver monitors all business processes in order to improve the effectiveness, efficiency and quality of its processes, products and services. Viraver systematically controls its products before delivery with the aim to verify the customer’s standards, and in particular in particular the optics, aesthetics and dimensions of the products. The checks on the finished products are carried out by qualified national experts.

Technologies

Balustrades

Certified by naval regis tries through impact test, linear load test and FEM. Suitable for installations with or without handrail. The increasing demand for a minimalist look and the current cutting-edge technology, led designers to aim at lighter, stronger and safer railings. The elegance and the strength of glass make it possible to create neat-looking bulwarks while complying with the strictest safety requirements.The edges get highly polished so that handrails and mullions are no longer necessary neither for structural nor aesthetic reasons.

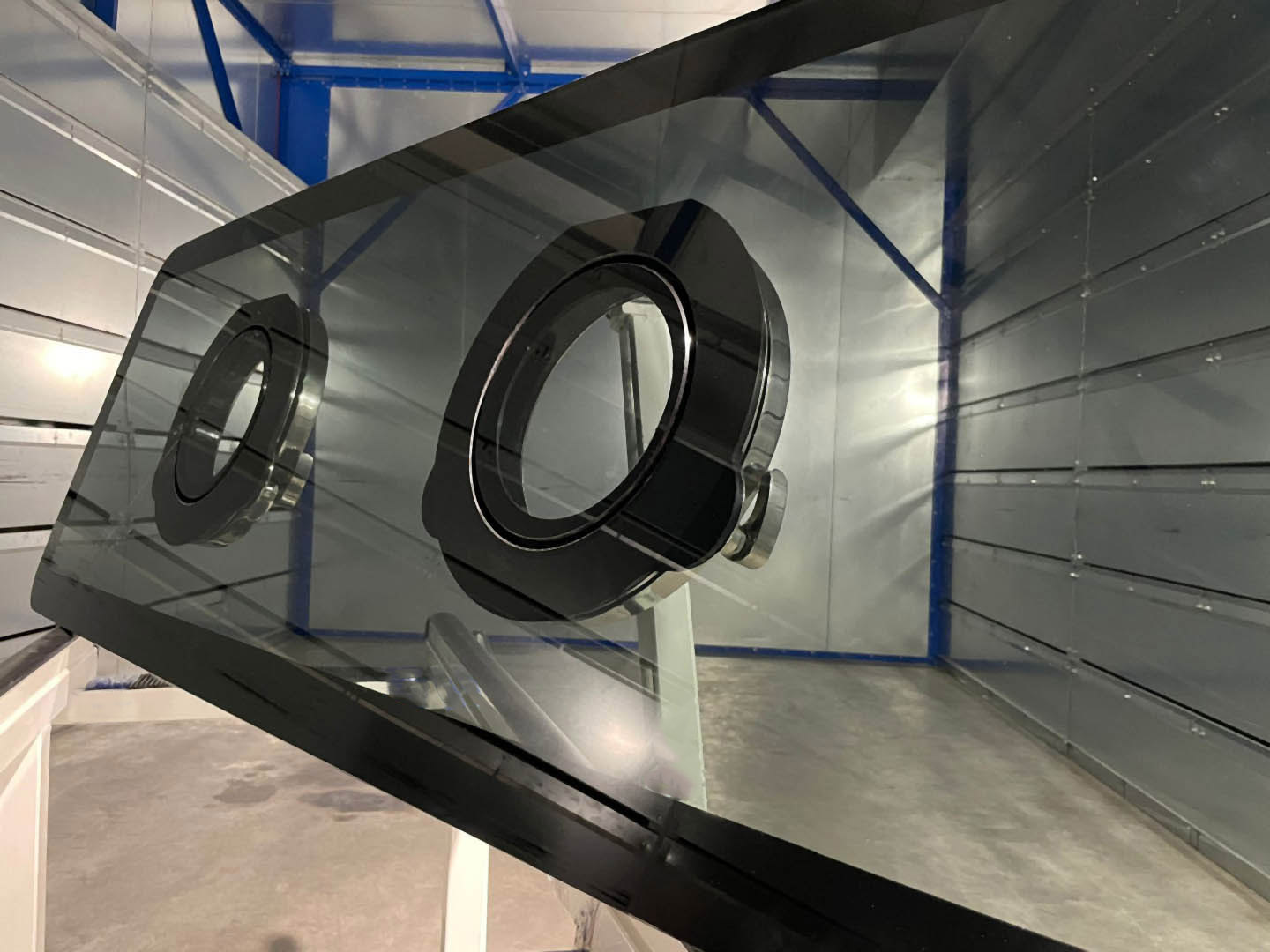

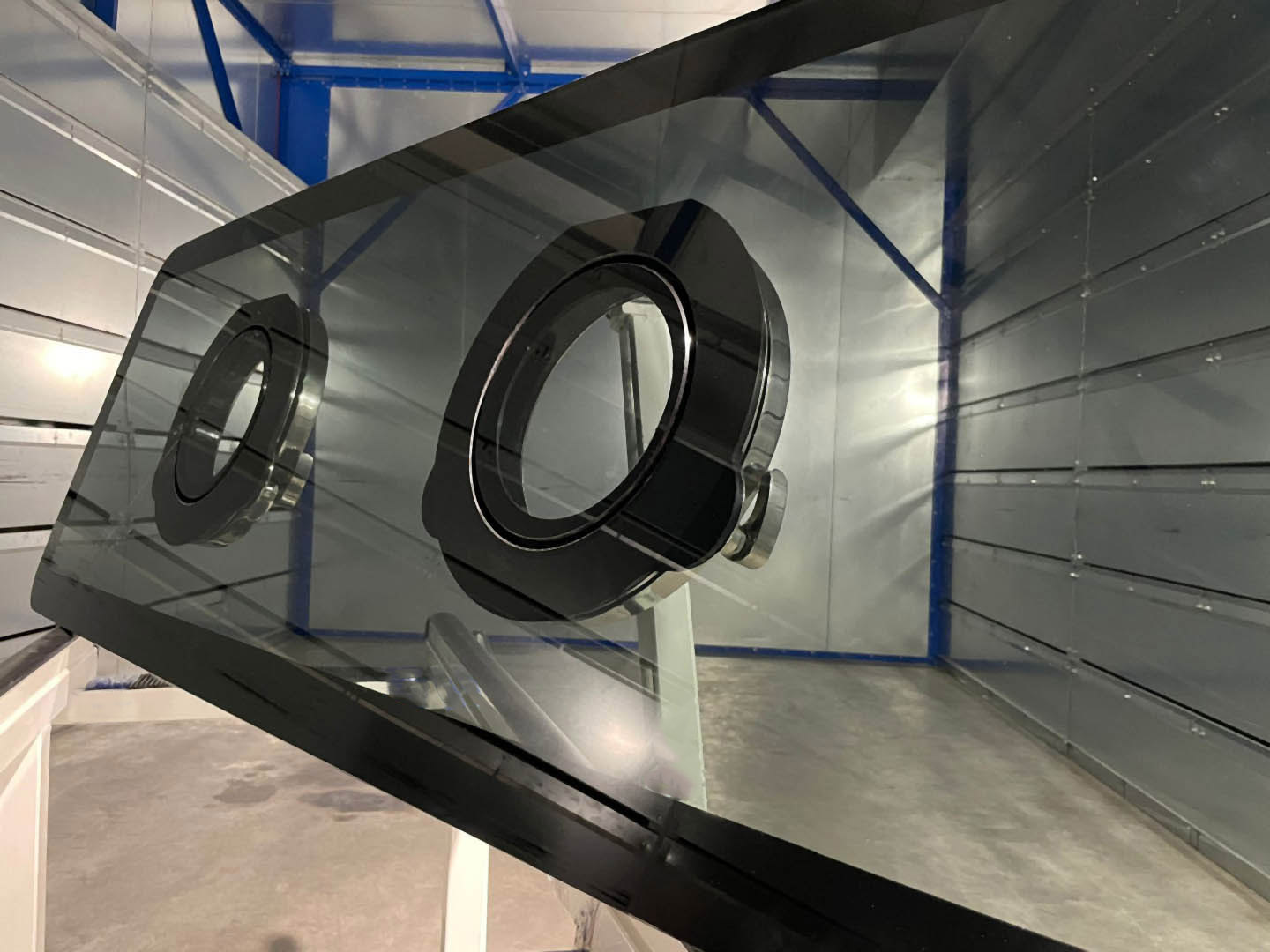

Integrated Porthole

Viraver Technology introduce a new technology for hull windows with portholes with integrated wireless sensor, flush installed to look completely frameless and compliant with the class requirements of all major naval registers. This technology is available for hull windows with different shapes: flat, curved cylindrical and curved spherical.

Viraflame®

Nowadays, during the stages of development of Super and Giga Yachts, the fire resistance characteristic is more and more frequently requested; this property is determined through the application of the Fire Test Procedure Code issued by the IMO. Viraver has introduced to this specific safety sector a fire protection system of excellence, which confirms Viraver Technology’s leadership in the yachting sector.

Viragrip

Viraver has qualified a particular product with a specific non-slip function. It is a laminated glass on which on its surface has been deposited a non-removable paint that significantly increases the roughness of the glass. It is possible to deposit the paint on the entire surface or to respect a specific design, such as a logo or dotted grid, to maintain the transparency of the element.

Virasun

In order to optimize the optical-luminous performance of the glass, in addition to providing a wide range of coatings available on the market, which can be adapted to complex shapes, Viraver uses shielding solutions through the use of special interlayers or selective films incorporated within the plastic interlayer.

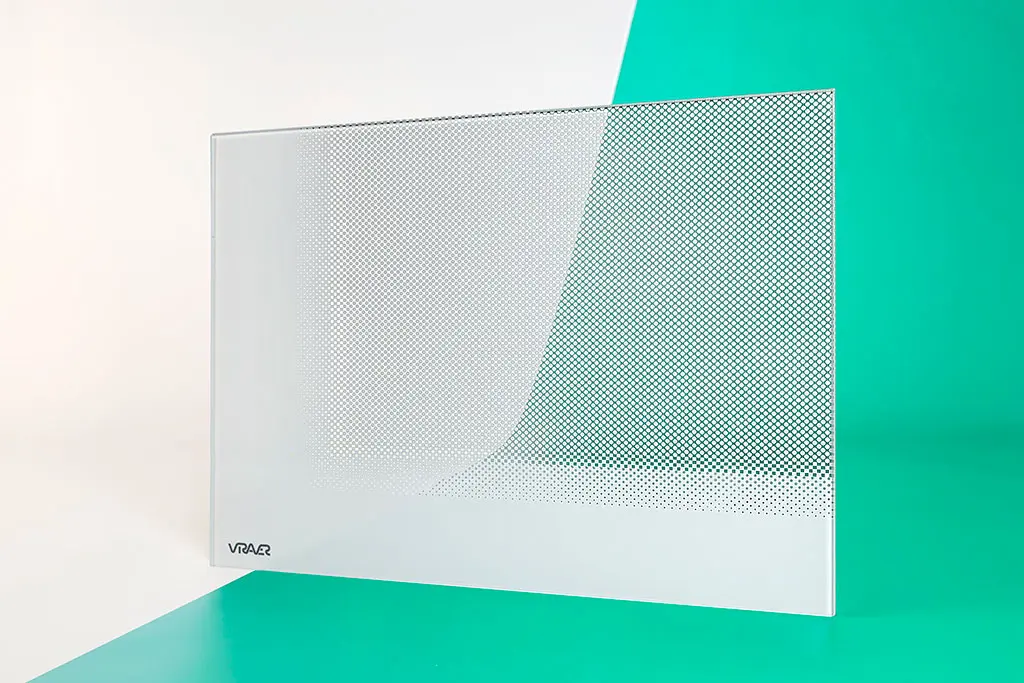

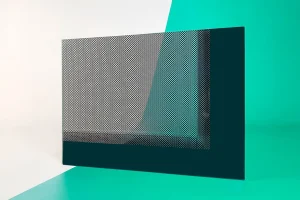

Virascreen

Privacy and protection are provided by windows that allow screening of electromagnetic emissions. By applying the Faraday Cage principle and ensuring a good compromise between visibility and the required shielding value, laminated glass shielding electromagnetic radiation is produced, attenuating it within certain frequency bands.

Shadyglass®

For indoor privacy management where traditional curtains are not used, windows are For the maintenance of privacy in rooms, in the absence of traditional blinds, there are windows that can be made opaque with a simple electric control. This effect is obtained by interposing a specific encapsulated film containing liquid crystals. When the film is active, (giving tension) the glass plate is rendered transparent, when turned off, the plate assumes a translucent-opaque appearance.

Virashield BR

Viraver offers a full range of bulletproof and anti-burglary solutions, certified according to different levels of protection. ViraShield BR (bulletproof glass) is a laminated glass composed of glass and polycarbonate sheets, joined together by the use of specific interlayers; all Virashield BR compositions are anti splinter.

Balustrades

Certified by naval regis tries through impact test, linear load test and FEM. Suitable for installations with or without handrail. The increasing demand for a minimalist look and the current cutting-edge technology, led designers to aim at lighter, stronger and safer railings. The elegance and the strength of glass make it possible to create neat-looking bulwarks while complying with the strictest safety requirements.The edges get highly polished so that handrails and mullions are no longer necessary neither for structural nor aesthetic reasons.

Integrated Porthole

Viraver Technology introduce a new technology for hull windows with portholes with integrated wireless sensor, flush installed to look completely frameless and compliant with the class requirements of all major naval registers. This technology is available for hull windows with different shapes: flat, curved cylindrical and curved spherical.

Viraflame®

Nowadays, during the stages of development of Super and Giga Yachts, the fire resistance characteristic is more and more frequently requested; this property is determined through the application of the Fire Test Procedure Code issued by the IMO. Viraver has introduced to this specific safety sector a fire protection system of excellence, which confirms Viraver Technology’s leadership in the yachting sector.

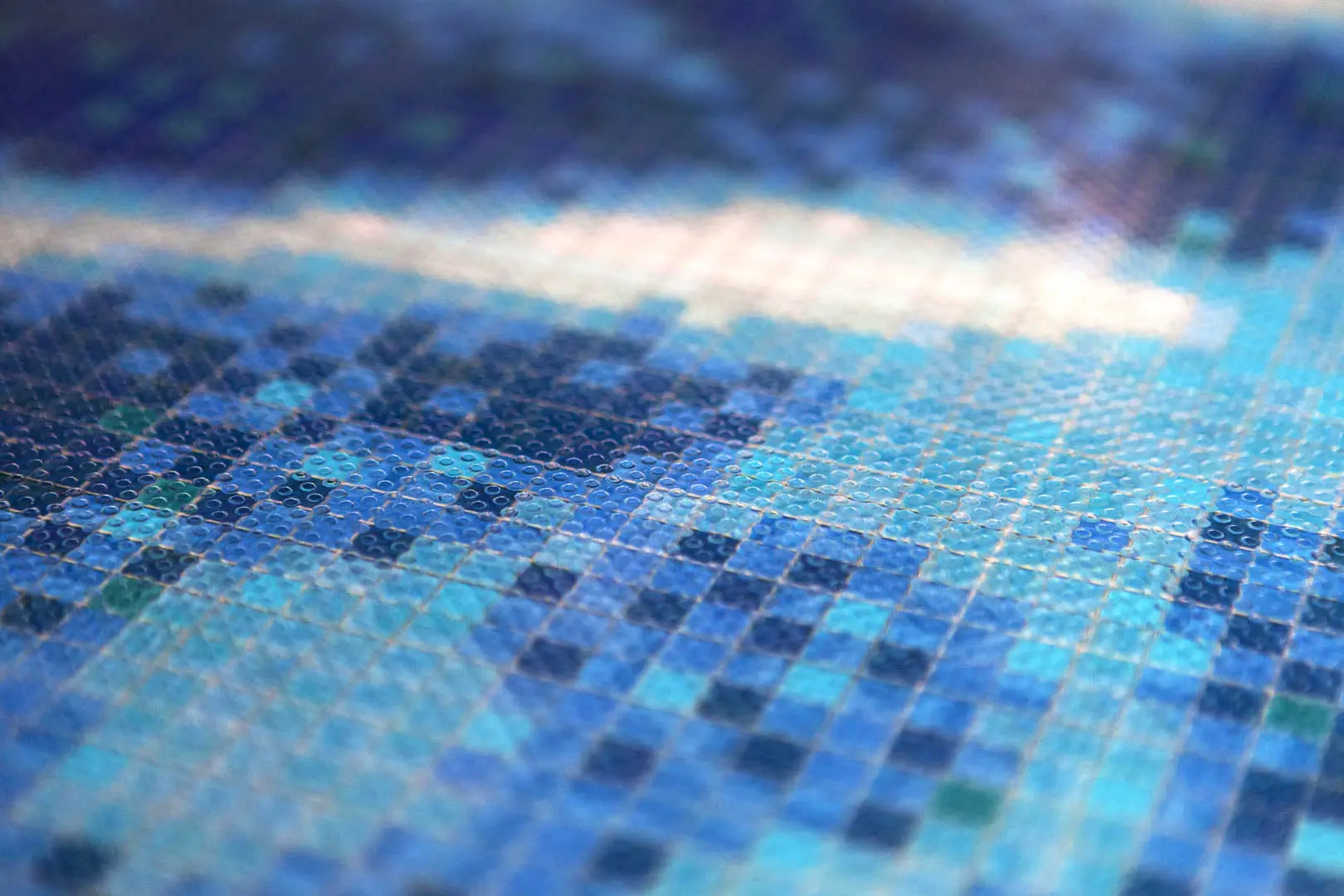

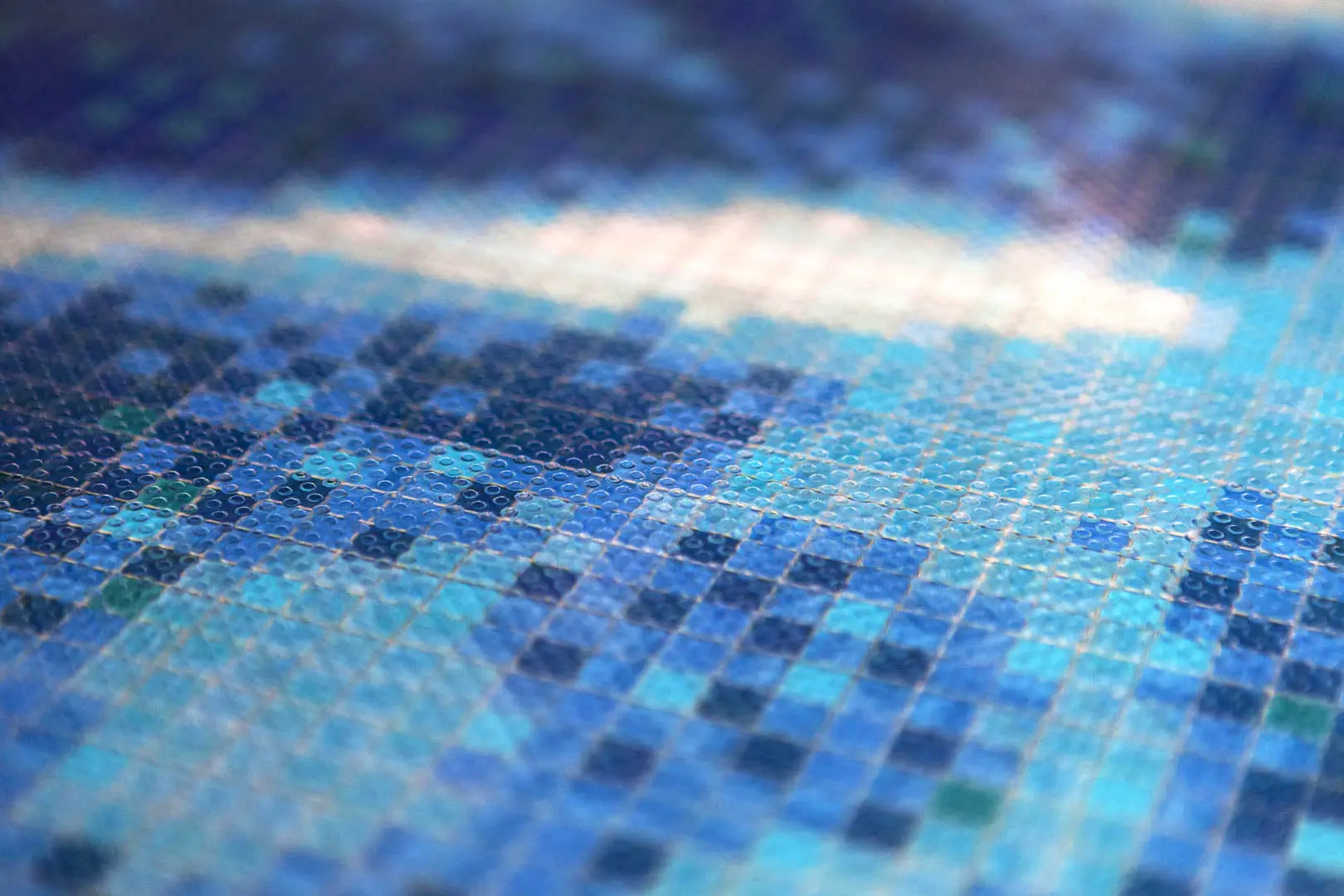

Viragrip

Viraver has qualified a particular product with a specific non-slip function.

It is a laminated glass on which on its surface has been deposited a non-removable paint that significantly increases the roughness of the glass.

It is possible to deposit the paint on the entire surface or to respect a specific design, such as a logo or dotted grid, to maintain the transparency of the element.

Virasun

In order to optimize the optical-luminous performance of the glass, in addition to providing a wide range of coatings available on the market, which can be adapted to complex shapes, Viraver uses shielding solutions through the use of special interlayers or selective films incorporated within the plastic interlayer.

Virascreen

Privacy and protection are provided by windows that allow screening of electromagnetic emissions. By applying the Faraday Cage principle and ensuring a good compromise between visibility and the required shielding value, laminated glass shielding electromagnetic radiation is produced, attenuating it within certain frequency bands.

Shadyglass®

For indoor privacy management where traditional curtains are not used, windows are For the maintenance of privacy in rooms, in the absence of traditional blinds, there are windows that can be made opaque with a simple electric control.

This effect is obtained by interposing a specific encapsulated film containing liquid crystals.

When the film is active, (giving tension) the glass plate is rendered transparent, when turned off, the plate assumes a translucent-opaque appearance.

Virashield BR

Viraver offers a full range of bulletproof and anti-burglary solutions, certified according to different levels of protection. ViraShield BR (bulletproof glass) is a laminated glass composed of glass and polycarbonate sheets, joined together by the use of specific interlayers; all Virashield BR compositions are anti splinter.