The glass

Viraver is synonymous with technological innovation and continuous research in glass development

We develop and produce flat and curved glass, both monolithic and laminated, studying tailor-made solutions for different sectors: yachting, automotive, architecture, industry, defence, and security.

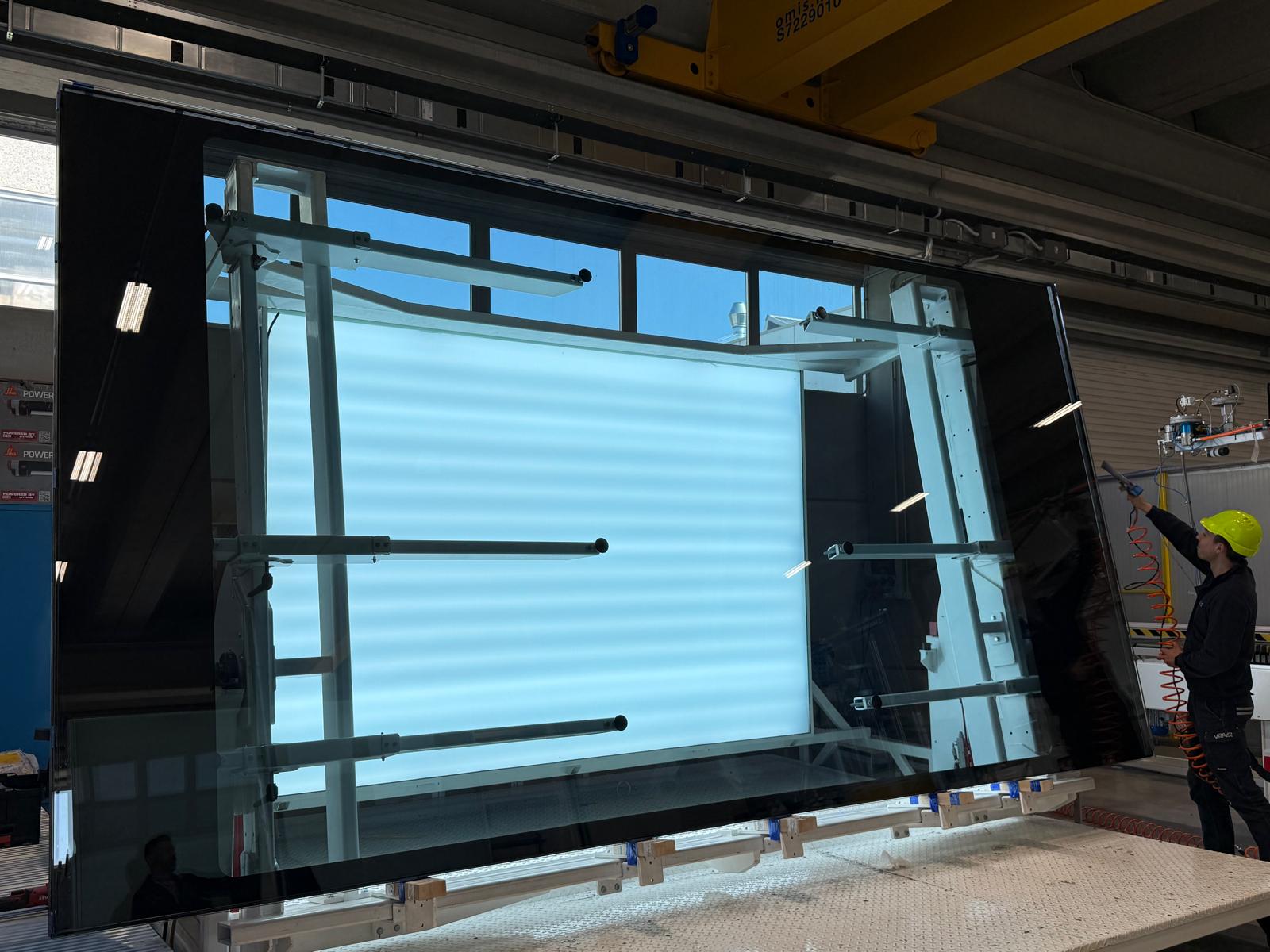

Our experience allows us to develop projects by combining the specific needs of each, respecting international laws and regulations. Viraver is a leader in the design and production of large glass, guaranteeing maximum safety and structural strength, reducing thickness without compromising quality and structure.

Glass Processes

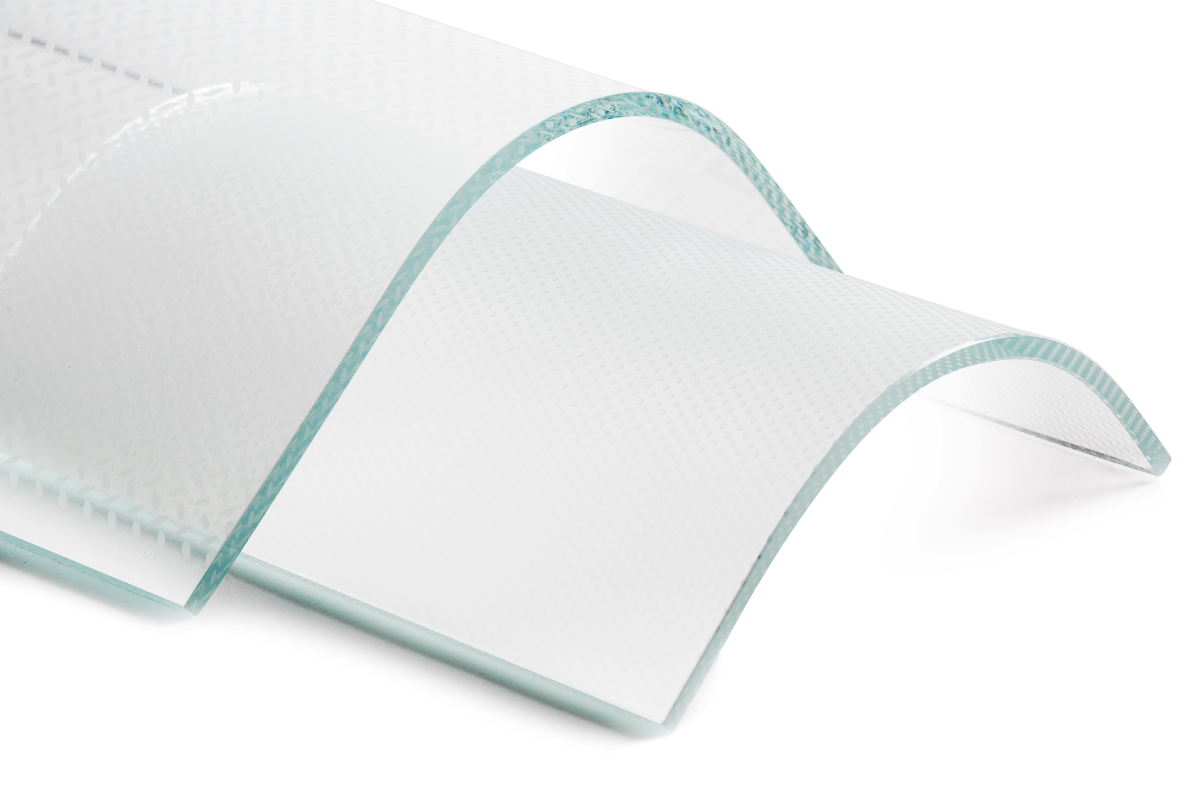

Viraver is a leader in the production of large, curved surfaces through gravity bending technology. This solution allows for cylindrical, spherical, and helical curvatures, even on very thick glass, ensuring excellent optical quality, free from defects, distortions, and undulations.

Thanks to the Viraver experience in complex curvature and the integration of 3D processing tools, Viraver creates complex glazing structures with perfect geometries, even in the most complex projects. Our technology pushes the dimensional boundaries of curvature, reaching sizes up to 6.50 m x 3.20 m.

Viraver uses the chemical strengthening process to give the glass characteristics of maximum resistance and unparalleled aesthetic/optical quality:

- Greater resistance: Maximum resistance to impacts, stresses and thermal shocks.

- Optical quality: The process maintains the transparency of the glass, and the total absence of optical distortions.

- Safety: Chemical hardening eliminates the risk of spontaneous breakage from nickel sulphide inclusions.

- Large dimensions: Viraver produces chemically strengthening glass sheets up to 8.00 m x 3.20 m.

The chemical strengthened process of glass is the ideal choice for all high-strength applications with excellent optical quality requirements.

Silkscreen printing is a glass printing process that has aesthetic and functional purposes, as it helps to safeguard the quality of the bonding. It is achieved through printing, using screen printing frames and inks suitable for the creation of compact and shaded bands on glass or plastic interlayers.

Laminated glass is the ideal solution for projects that require transparency, resistance and safety, in compliance with required standards.

Viraver produces high-quality laminated glass, processing each element through the bag technique and autoclave cycle.

The assembly process takes place in a clean room, thus guaranteeing the total absence of inclusions and maximum precision during the entire production process.The layering techniques used at Viraver allow countless materials to be inserted into the plastic interlayer, which give the glass additional performance, such as:

- Heating systems:to ensure maximum visibility in all conditions

- Thermal control:for energy saving and internal temperature control

- Electromagnetic shielding:for protection against interference

- Electrically controlled matting films:for privacy and brightness adjustment

- Decorative prints:to customize the aesthetic appearance of the glass

This is the process in which the glass and the plastic material that make up the laminate are joined. Viraver performs autoclave lamination, which consists in subjecting the laminate to the simultaneous action of pressure, temperature and vacuum to generate the union of the different materials.

Viraver has two glass lamination plants, capable of processing large sheets up to 9.00 m x 3.20 m.

Viraver is ISO 9001: 2015 certified and applies a rigorous quality management system at every stage of the production process. We continuously check our procedures to optimize the effectiveness, efficiency, and quality of our products and services. Ahead of delivery, each product is subjected to meticulous checks by qualified personnel to ensure it complies with the customer’s requirements, with a particular focus on:

- Optical testing

- Dimensional testing

- Aesthetic testing

TECHNOLOGIES APPLIED TO GLASS

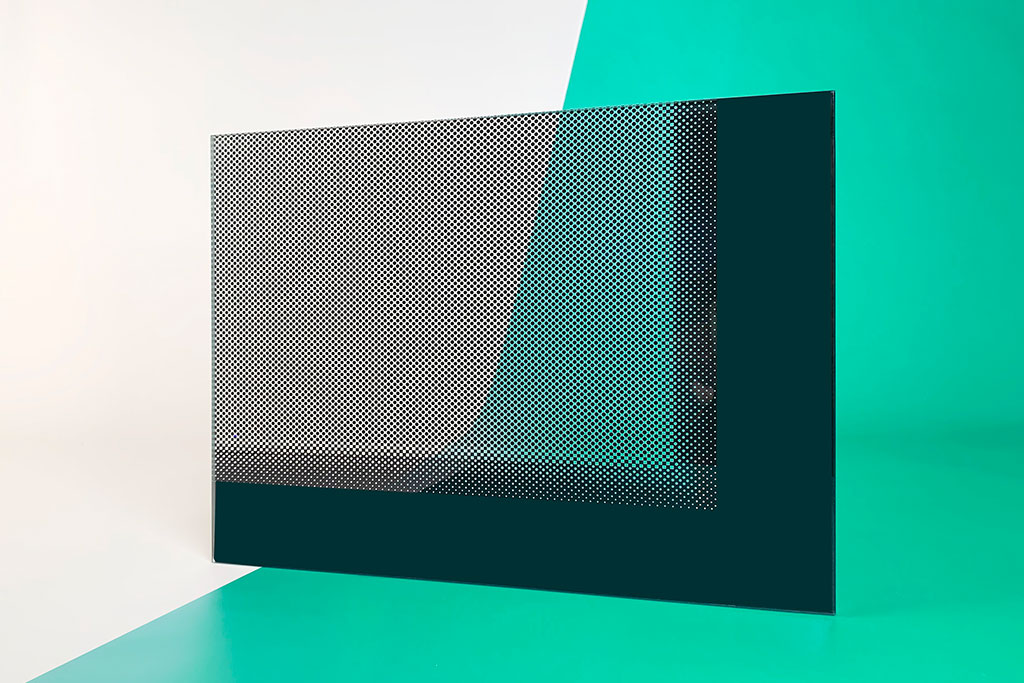

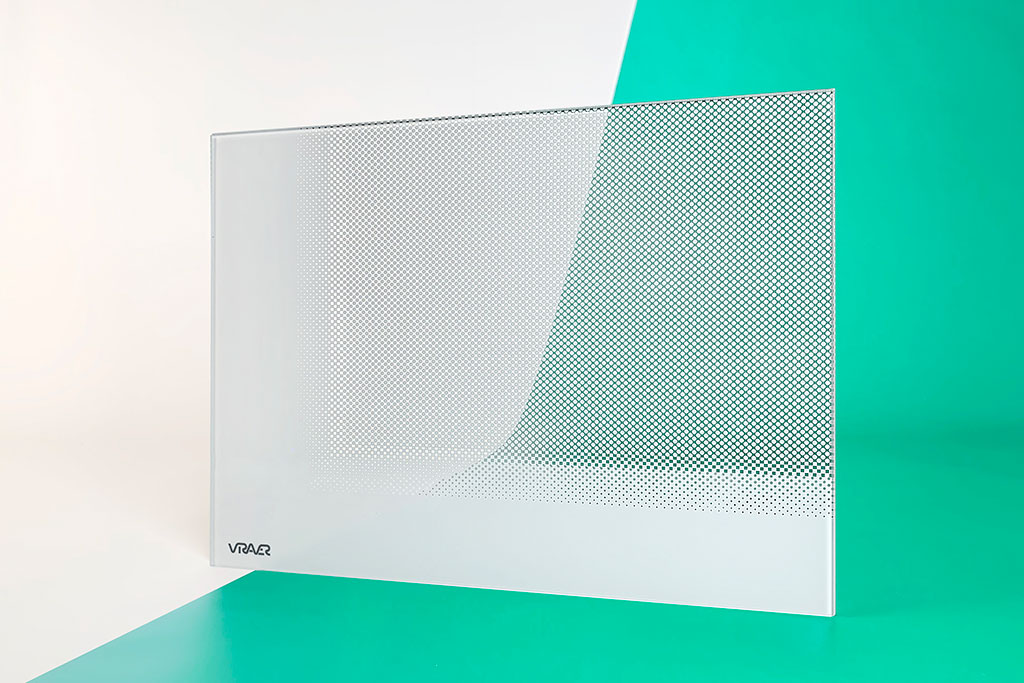

ViraPlain

ViraPlain is a product that merges aesthetics and privacy through its innovative technology. It is a glass with a double layered dots screen printing technology, featuring an external surface that blends chromatically with the hull’s colours, creating near-total consistency. The internal surface is black, providing excellent visual shielding and privacy. The privacy within the rooms is ensured by the shape of the dots, which, by interrupting the direct or indirect light source, enhance the shielding from the outside to the inside, creating a private and comfortable space.

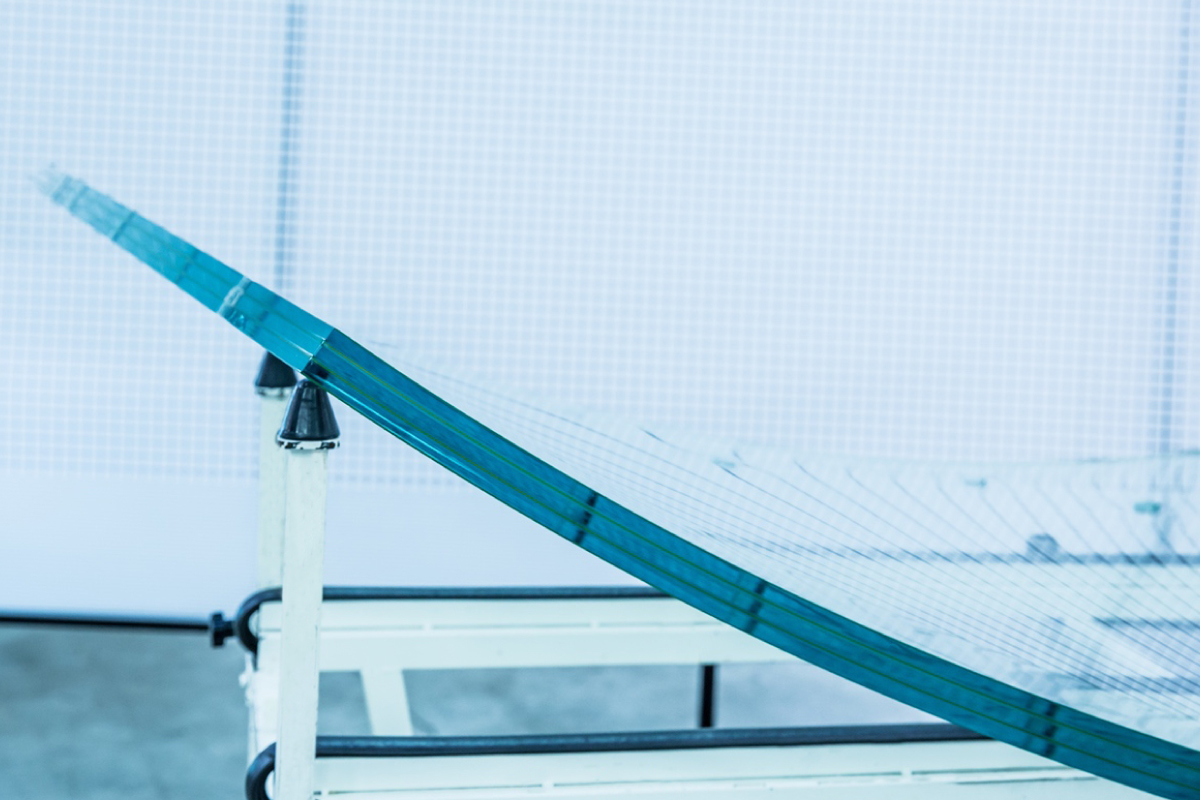

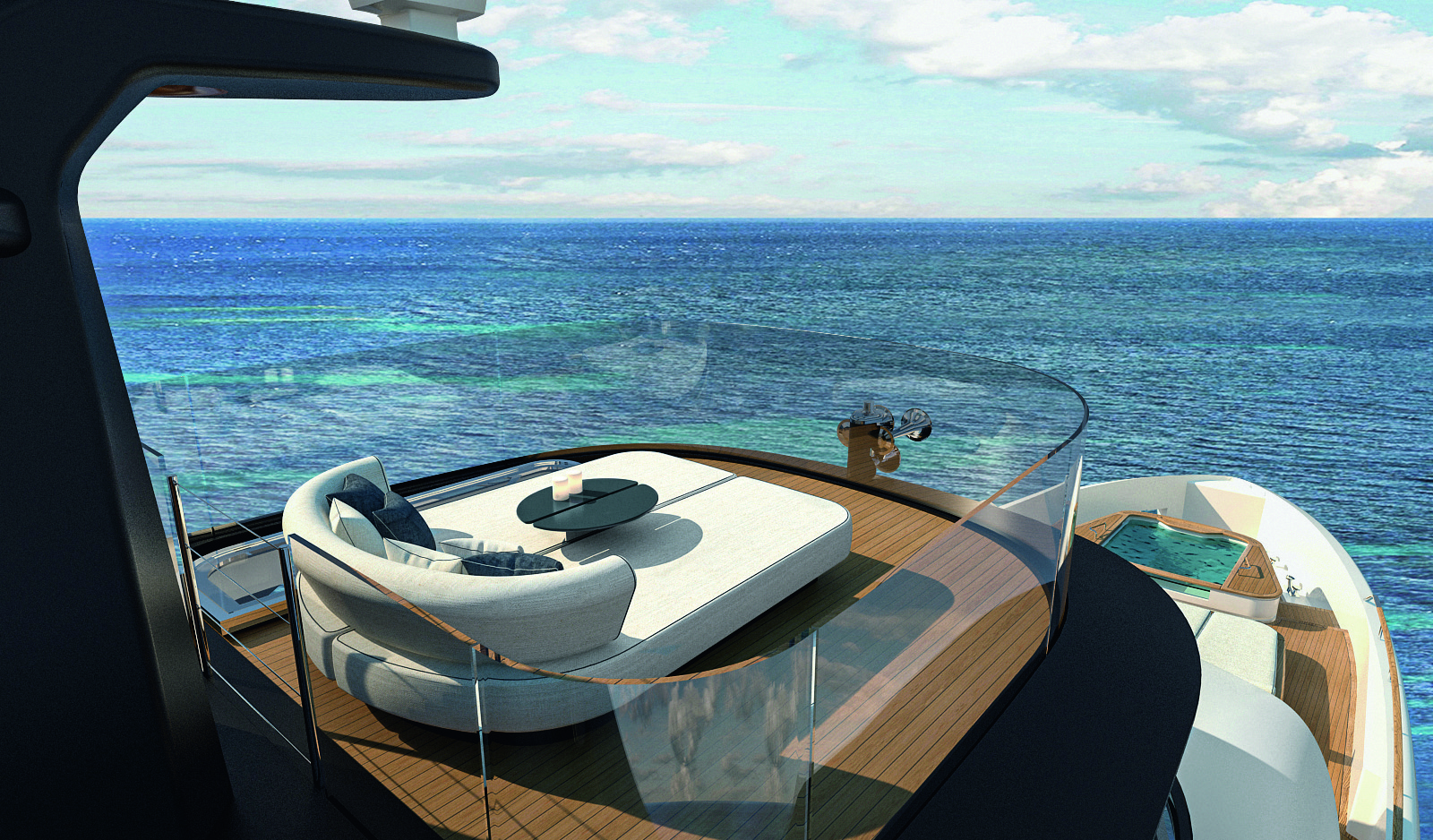

Balustrades

Viraver glass balustrades are certified by the main naval registers thanks to rigorous impact tests, linear load tests, and FEM (Finite Element Method) analysis. They can be installed with or without handrails, always ensuring the highest safety standards required by up-to-date yachts.

The search for a minimalist design and continuous technological progress have allowed for the development of increasingly lighter glass parapets, without compromising on strength and safety. The use of chemically tempered glass with finely polished edges allows for the elimination of uprights and handrails for both structural and aesthetic goals, giving rise to elements with a fluid and elegant design.

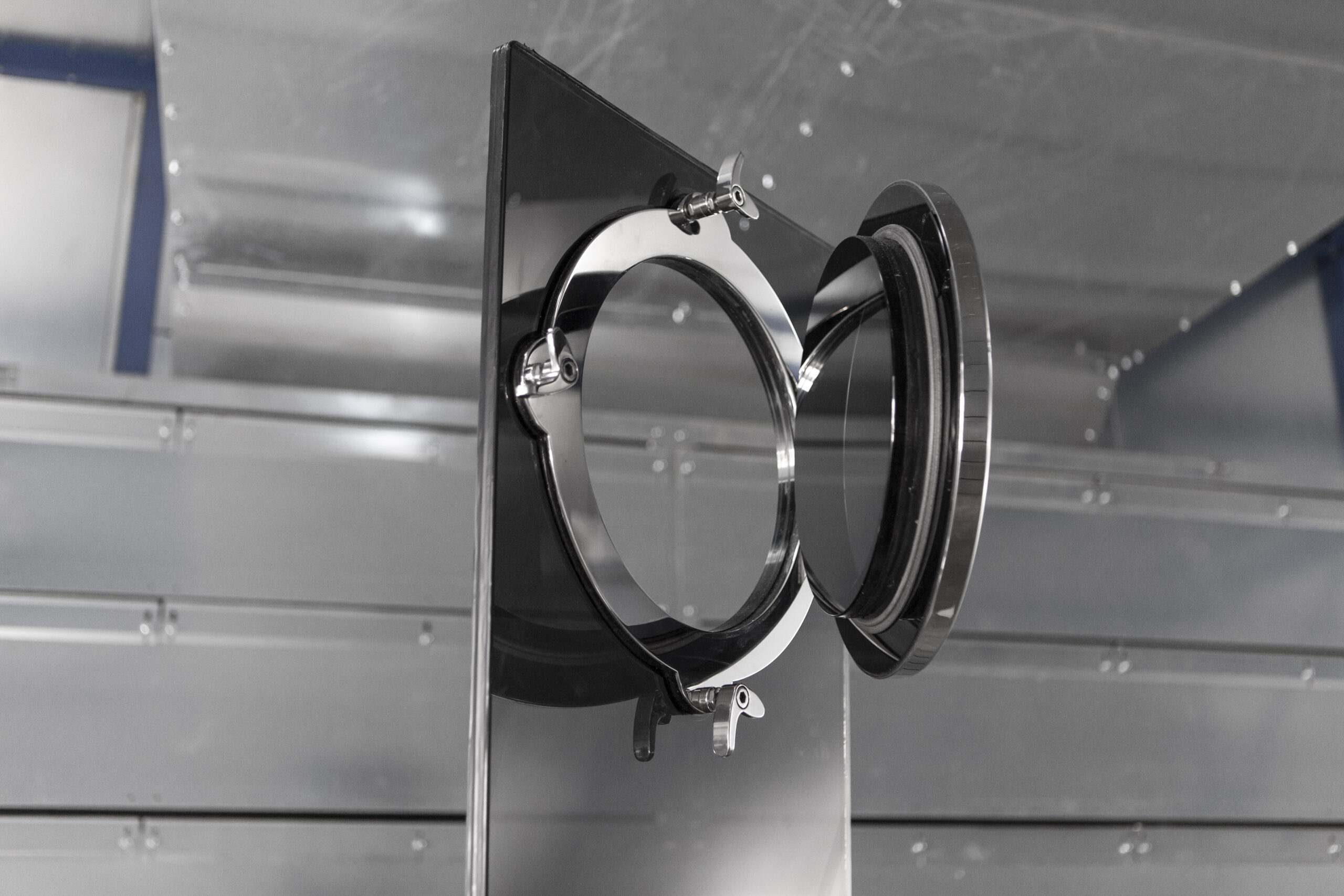

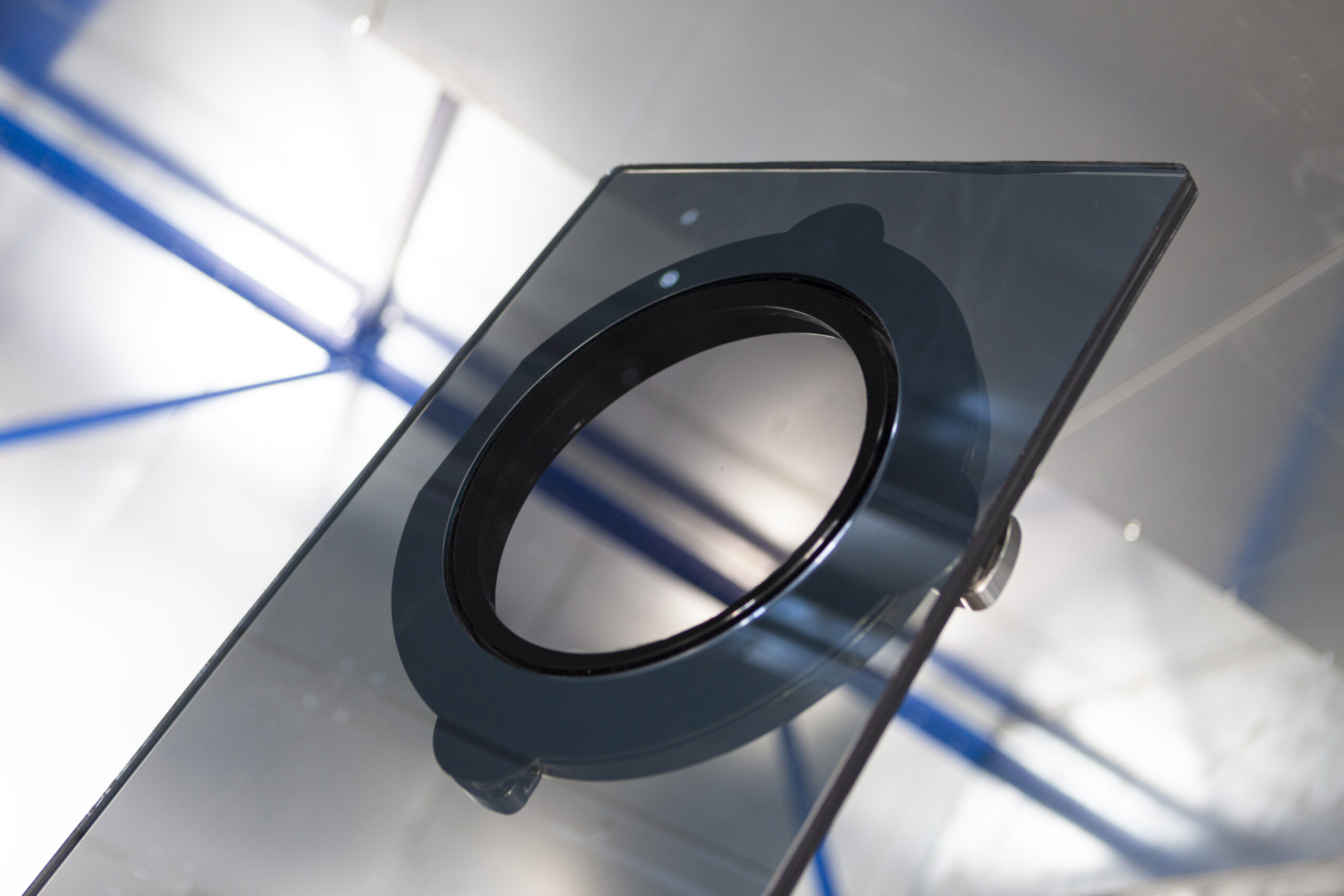

Hull windows with integrated portholes

Viraver develops innovative hull windows, equipped with integrated portholes with wireless sensors. This technology allows for surfaces that are completely flush with the hull, without visible frames, guaranteeing a refined aesthetic and fully complying the certification requirements of naval registers. Viraver offers these elegant elements in flat, cylindrical and spherical surfaces, providing customized solutions that integrate perfectly with the hull design. Viraver’s hull windows with integrated portholes express functionality, innovation and elegance.

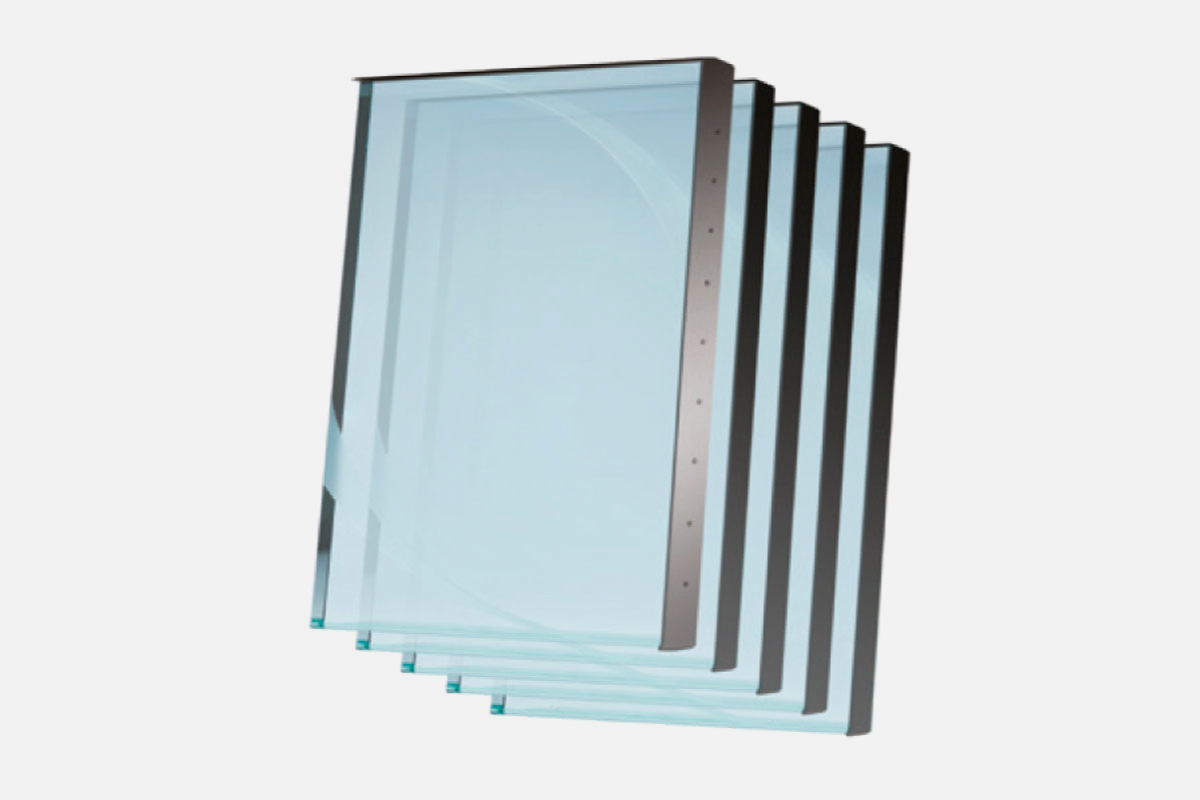

Large Double Glazing

Viraver designs and manufactures high-performance, custom-made double glazing, ideal for optimizing energy efficiency and comfort on board. They are available in both flat and curved versions, reaching the maximum dimensions allowed by glass sheets on the market and satisfying even the most demanding design needs. Viraver’s innovative double glazing integrates the latest thermal and acoustic insulation technologies, ensuring an excellent U-value, a significant reduction in noise and an overall improvement in energy performance, without aesthetics compromising.

Submerged or semi-submerged windows

The design of modern Mega and Giga Yachts increasingly requires the presence of submerged or semi-submerged windows, which replace traditional portholes with continuous structural glazed surfaces. Thanks to cutting-edge technologies and advanced engineering expertise, Viraver designs and manufactures these solutions, ensuring maximum safety, durability, and reliability even in the most extreme conditions. Each project is developed in close collaboration with the shipyard and Viraver’s integrated project management, providing the best solution in terms of aesthetics and functionality. These innovative windows enhance the yacht’s design, providing brightness and direct contact with the sea.

ViraFlame: Fireproof Glass

ViraFlame® revolutionizes the concept of fire-resistant glass with innovative technology. It is a certified system that perfectly combines safety and design needs, offering superior quality compared to fire protection systems on the market, in terms of thickness reduction, transparency and stability over time. The ViraFlame fireproof system does not require the use of intumescent gel but exploits the design innovation related to the frame, the type of fixing and the sequence of materials installed.

- The classification obtained, in accordance with the FTP tests, is A0 (extendable to A30 with dedicated sprinklers) and with maximum element dimensions of 3.00 m X 2.00 m.

- Reduction of thicknesses

- Unchanged transparencyand reliability over time, even in fire conditions, unlike systems with intumescent gel

- Compliant with the requirements of the Passenger Yacht Code – CISR.

ViraGrip

ViraGrip is a non-slip laminated glass with a non-removable paint that significantly increases the roughness of the surface, ensuring maximum safety even in humid environments or for outdoor applications.

The treatment can be customized with logos or geometries while maintaining the transparency of the glass.

ViraHeat

Viraver produces flat and curved glass with heating systems, with a de-fogging or de-icing function, guaranteeing maximum transparency and visibility even in adverse weather conditions. Customizable in terms of supply voltage, unit heating power and energy consumption.

The heating effect can be obtained with two different technologies:

- Heating micro-wires

- Conductive coatings

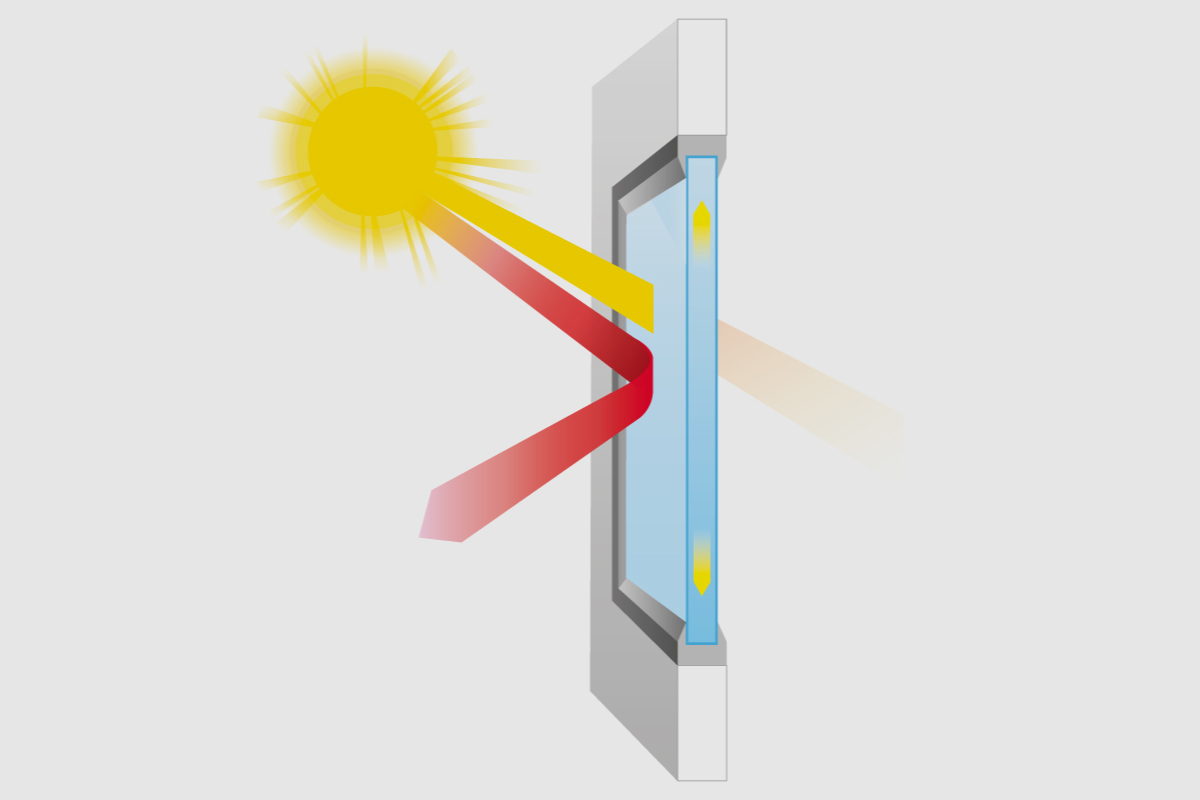

ViraSun

ViraSun is an innovative solar shading solution for improving the optical-energy performance of glass. Thanks to selective films and special interlayers integrated into the laminated glass, ViraSun adapts to even the most complex shapes.

The IR filter reduces up to 50% of infrared radiation, contributing to cooler environments and greater living comfort. It also promotes significant energy savings and a lower environmental impact.

Virascreen

Virascreen windows ensure privacy and protection by screening out electromagnetic emissions. Applying the Faraday cage principle and ensuring a good balance between visibility and the required protection value, laminated glass is produced to block electromagnetic radiation.

Shadyglass

Shady Glass, una soluzione innovativa di Viraver per la privacy senza tende. Grazie a un film incapsulato contenente cristalli liquidi, si possono rendere trasparenti o opache le vetrate con un semplice comando elettrico. Quando attivio il vetro è trasparente; spento, diventa translucido o opaco, garantendo privacy e comfort. Completamente sicuri e conformi alle normative CE, i vetri Viraver Shady Glass uniscono funzionalità, sicurezza ed elegante design.

Glazed Deadlights

Viraver glazed deadlights are manufactured in accordance with ISO 11336 and are certified by leading naval registries as an innovative solution to traditional metal reinforcements for mega and giga yachts. This advanced nautical glass technology makes possible the installation of large flat or curved windows, giving yacht designers maximum design freedom.

In addition to enhancing the aesthetics of yacht interiors, Viraver glazed deadlights improve onboard safety, ensure excellent light transmission, and provide optimal visibility for an engaging sailing experience. Viraver supports the shipyard throughout the approval process, coordinating the required naval tests and ensuring full compliance with the current regulations in the yachting sector.

ViraShield BR: bulletproof glass

ViraShield BR is a high-quality, lightweight, bulletproof laminated glass, certified according to international safety standards and composed of glass and polycarbonate sheets, joined by specific interlayers. It guarantees ballistic protection and maximum safety against bullets and impacts. All Virashield BR compositions are anti-splinter.

ViraShield BR combines safety and custom aesthetics. During the design phase, bulletproof (ViraShield BR) and anti-burglary (Viralam) products can be adapted to the customer’s architectural and design needs using heating systems and/or opacifying films. The goal is to make the armoured model indistinguishable, both in terms of aesthetics and optical quality, also through the considerable reduction in thickness. Viraver has numerous compositions classified in accordance with the international reference standards EN 1063 (in the civil field) and STANAG 4569 (in the military field).