The Polycarbonate

Viraver, a leader in polycarbonate processing, offers customized solutions by designing and manufacturing complex models

Our experience, appreciated by the main automotive brands, guarantees high-precision products and security solutions. Polycarbonate is a plastic material with qualities of lightness, transparency, strength, and resilience, ideal for applications that require innovative, lightweight, and safe solutions.

Viraver stands out for its ability to transform polycarbonate into products with complex and customized shapes, respecting the highest quality standards.

Polycarbonate processes

Laminated polycarbonate is one of the most used products because it allows for combining transparency with the characteristics of strength and safety required by the mandatory standards.

The stratification techniques used in Viraver allow for the insertion of heating devices in the plastic interlayer, which give the polycarbonate additional performance.

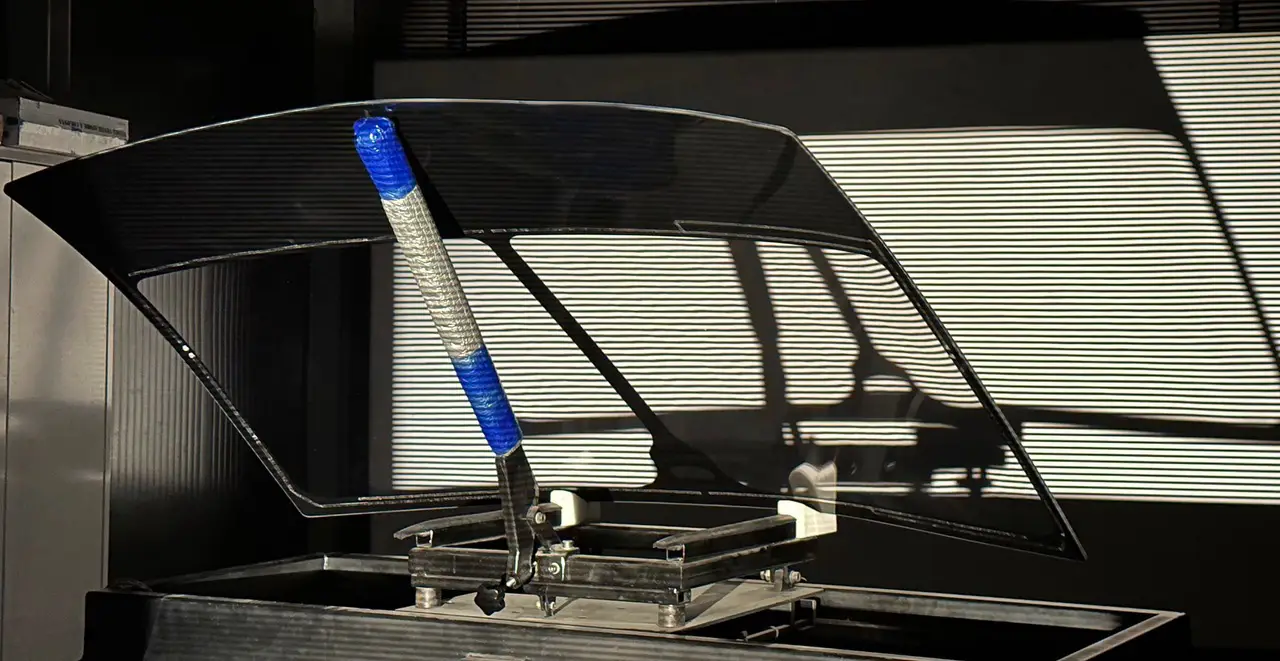

Autoclave lamination is the process in which the polycarbonate and the plastic material are joined, through the simultaneous action of pressure, temperature and vacuum to generate the union of the different materials that make up the laminate. Viraver can laminate large sheets up to 9.00 m x 3.20 m.

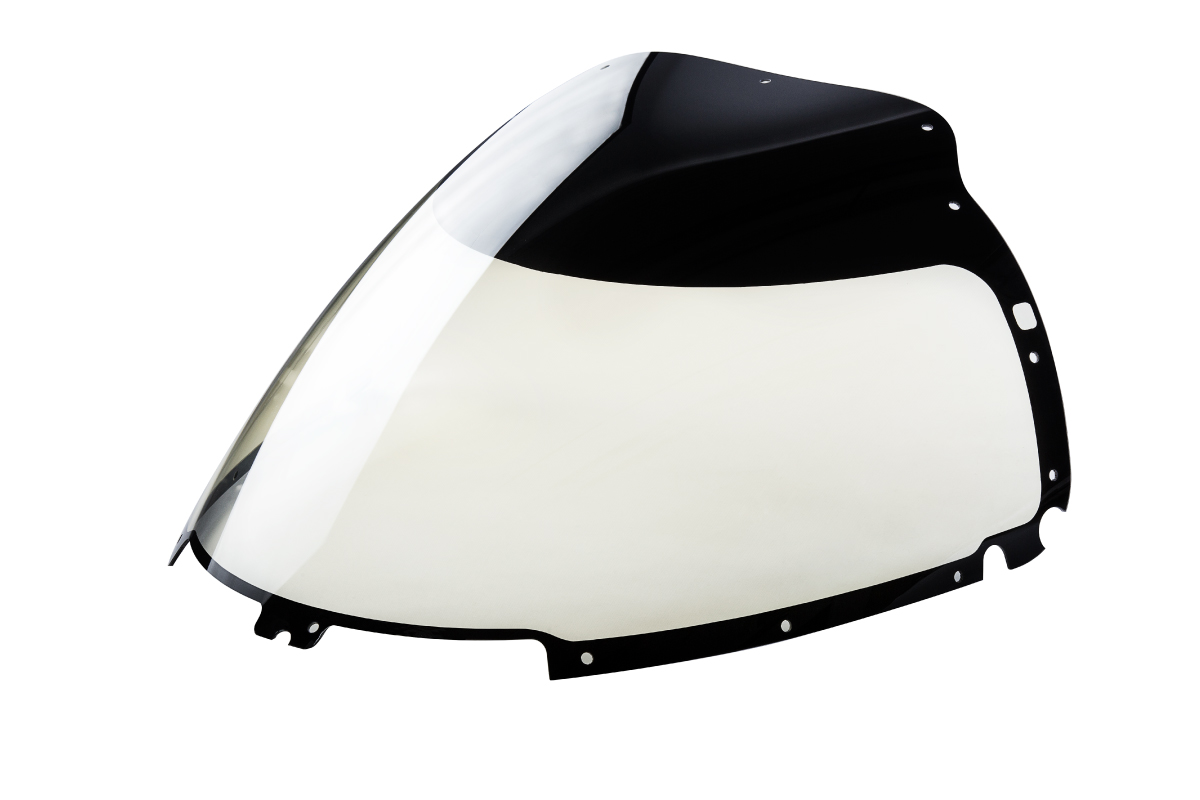

In the production of polycarbonate windscreens and windows, an extremely precise trimming phase is required to reach the dimensions defined by the customer and ensure perfect assembly. This activity is carried out using a five-axis machine (work area 6m x 3.3m), which allows perimeter trimming and/or other processes such as holes, incisions or notches.

Polycarbonate windscreens are essential components for the safety and visibility of the pilot. Viraver carries out accurate checks and tests in state-of-the-art test rooms, using precision technologies to detect any distortions and optical deviations.

All our products are tested and certified according to current international standards:

- DIN 52-305

- ECE – UN R-43

Technologies applied to polycarbonate

Infrared filter

Viraver applies special interlayers and selective films to reduce the effect of solar radiation by up to 55%, ensuring greater comfort, energy savings, and heat protection.

Heating Circuit

Viraver produces flat and curved transparent solutions with heating systems, with a de-misting or de-icing function, guaranteeing maximum transparency and visibility even in adverse weather conditions. Customizable in terms of power supply voltage, unitary heating power, and energy consumption.

The heating effect can be obtained using two different technologies:

- Heating micro-wires

- Conductive coatings

Anti-Scratch Coating

To increase the durability of polycarbonate products, Viraver has developed the application of a special anti-scratch coating that reinforces the surface, making it extremely more resistant than the original product. The product obtained complies with international standards (ECE R43, DOT).