MYS 2022

Beyond Glass 2030

Viraver’s company vision “Beyond Glass 2030” is our industrial plan aimed at an incremental growth which will see investment involving people and their training, new production plants and new technologies.

“Beyond Glass 2030” defines Viraver’s commitment to:

Being technologically advanced and innovative

Being a creator of unique productsImplementing co-marketing activities

Connecting with its customers

Becoming a more sustainable company

From 2020 to 2022 Viraver has acted:

- We have chosen and implemented an innovative scientific approach, applying Neuroscience, dedicated to the management team, to improve team performance.

- We have introduced Virtual Reality to train those in charge of safety in both production and other areas of the company.

- We have invested and expanded the production plant

Complex Curves

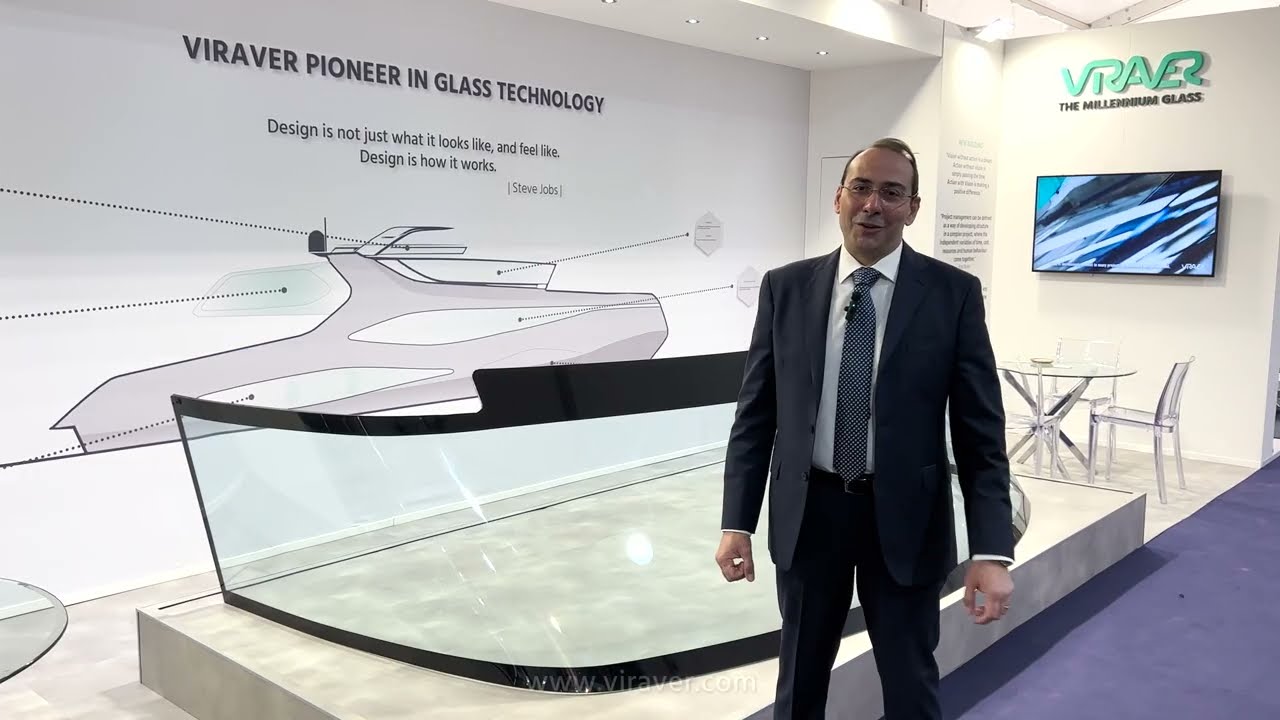

| Design is not just what it looks like and feels like. Design is how it works. |

Steve Jobs

Thanks to Viraver’s technological developments and ability to innovate, glass has taken on a role as a ‘functional design element’ in the nautical industry, thus assuming a structural, safety and design function. This is the case with the windscreen we are exhibiting at MYS 2022, unique in size and shape.

Shapes and new proportions had to be developed by Viraver in order to create a unique piece, approximately six metres long, with double curvature, that would dress the entire glass lap of the wheelhouse, joining for the first time central glass and side glass without the presence of uprights. In addition, given the large size of the glass surface we applied a technology to reduce the heat perceived inside the wheelhouse, a request to which Viraver responded with an innovative solution.

Moving the limits meant using all the new technologies available to Viraver, from chemical tempering to large-scale gravity bending. The product is a double curved laminated glass with a length of 5.7m, technically challenging gravity due to its cylindrical curvature at the centre, spherical at the corners and then helical at the extremities. The optical quality achieved, the absence of imprinting and optical distortion, which is essential for the context in which this product is applied, is further proof of Viraver’s technical capabilities.

Turnkey Project Management

Turnkey Project Management means that Viraver offers its customers its support from the pre-desing phase, when details are far from defined, to the installation and if requested maintenance as well.

In this context, Turnkey Project Management is the totality of the project manages by one or more specialized personnel – Project Manager – dedicated to analyzing, designing, planning and completing the objectives of the project.

Viraver, true to its DNA, has developed its personal approach to Turnkey Project Management based on a model of activities which are shaped on the needs of the customer, a strong point for the development of innovative products.

Refitting

For Refit, just like for a new project, it is advisable to rely completely on the Turnkey Management offered by Viraver. In so doing, such a complex project, can fully benefit from Viraver’s twenty year experience working closely with the project manager and the yard supporting with what we can pragmantically define as a “turnkey” service.

Refit today often means the complete overhaul of a yacht and this includes windows as well.

The replacement of windows on older boats requires competence and expertise. One of the challenges can be that technology used in the past is now obsolete and another can be that the project was from a different company.

In such cases, beside creating an adequate new window plan, it is necessary to effectively work together with the registries to present and get the approval for a new window plan.

Viraver Pioneer in Glass Technology

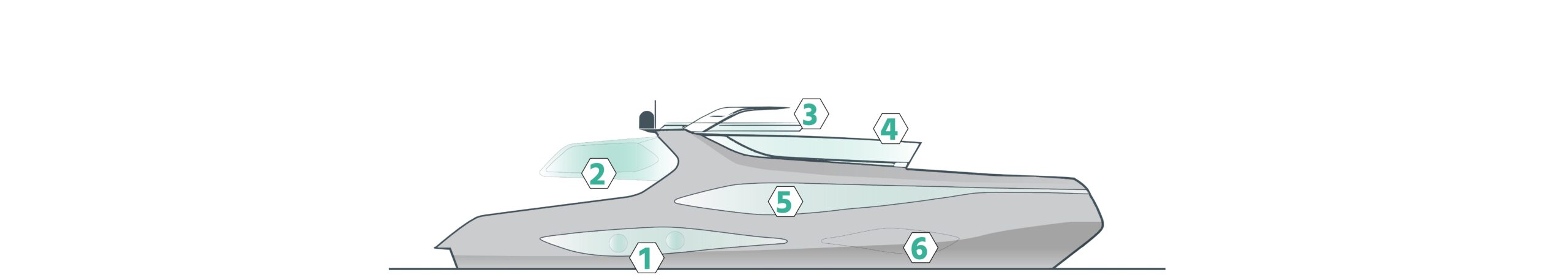

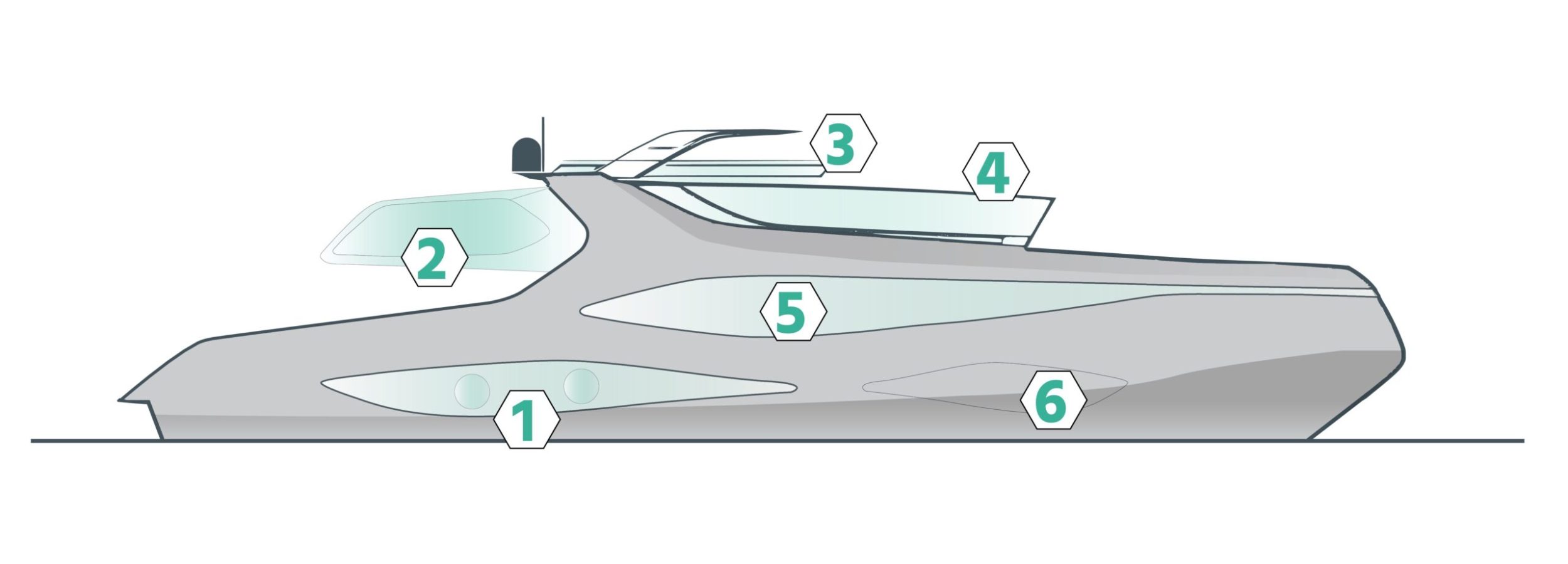

- Integrated Portholes – flush installed to look frameless and complying with the class requirements.

- Complex shapes – achieved through the combination of our experience in sag bending and the chemical toughening process.

- Balustrades – Certified by naval registries through impact test, linear load test and FEM. Suitable for installations with our without endrail.

- Viraheat – de-fogging or de-icing systems to ensure max visibility in all environmental conditions. Virasun – different technologies to filter IR and UV rays.

- Structural glass – compositions designed to perform a function not only aesthetic but also mechanical.

- Viraplain – double layered dot screen printing, matching the hull color on one side and black on the other, to embody aesthetic and privacy.