How Can We Reduce Weight to Save Energy ?

This was one of the Superyacht Forum topics for the future of Superyacht design.

Viraver’s answer to this topic is: the glazing systems, elements or structures, are today a functional design element, where it is no longer just a matter of pure design, but technology plays an important role.

Viraver, designs and produces the New Millenium glass, but what does it mean.

It means that Virvaver’s R&D team works to define new boundaries for the use of glass in a yacht, and it is firmly convinced that glass is one of the best choices for yacht designers and shipyards, to achieve the goal of weight reduction, which translates into energy saving.

Today, the use of advanced and quality glazing systems results in a more sustainable product, essential for new projects and even more so if we consider yacht refit.

Marco Mazzarolo, Viraver CEO and Francesco Visentin Technical Project Engineering have explained in a workshop the company’s Vision and solution to answer this question.

The drafting of a project for Viraver is the start of a new story.

To manage a new project Viraver applies its Integrated Project Management vision. This was developed on an activity model that is shaped on the needs of the customer, a winning factor in the creation of innovative products.

Six steps to work better together, and achieve the best result possible for the design of the New Millenium Glass, and once again, How Can We Reduce Weight to Save Energy?

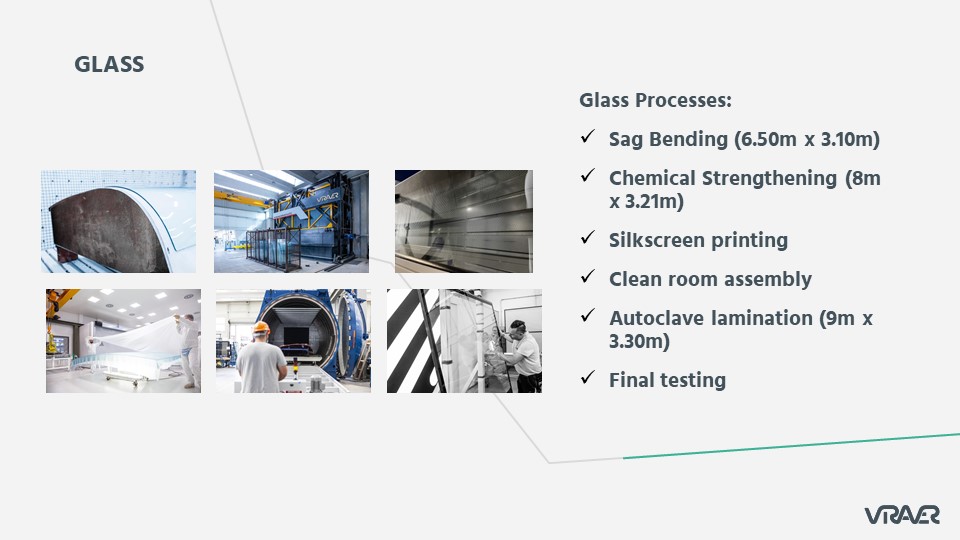

Focus on two principles: improving the energetic performances of the windows and reducing the weight of the glazing system. To reduce the weight of a glass, the Chemical Strengthening process is fundamental.

Glass gets soaked into a potassium nitrate bath for a certain amount of time depending on the level of performance to be achieved.

The ion exchange expands the glass volume on the surface creating a compression which makes it stronger and prevents cracks from opening.

The use of an Interlayer, it is equally indicated and brings considerable benefits.

Usually, glass plies get laminated together by means of PVB, a plastic material that gets produced in thin foils of different colors and with many specific functions such as noise-reduction or anti-IR. Nevertheless, when it comes to structural performances, engineers, architects, and designers can rely on Sentryglas: a special foil with enhanced mechanical properties.

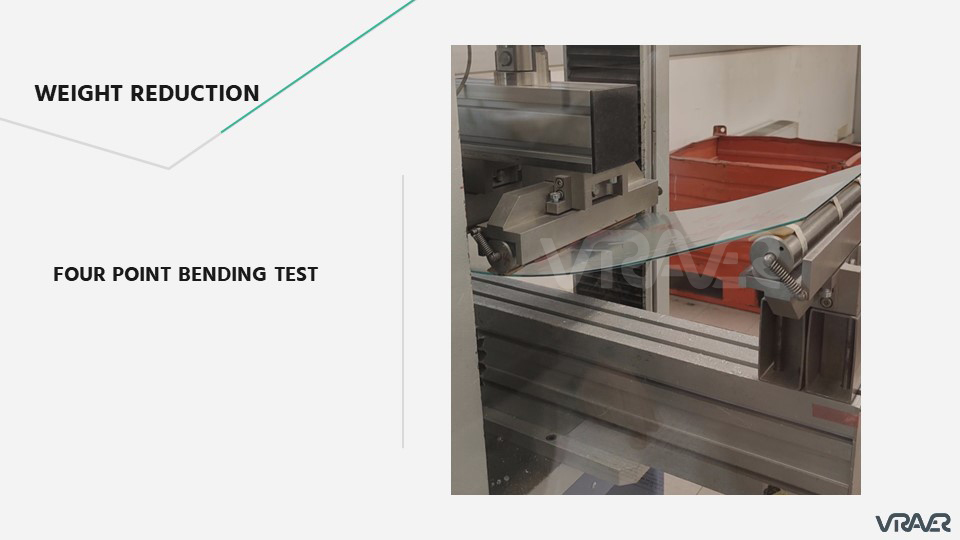

In Viraver, quality, rules, and regulations, are strictly followed, one of the principal actors of this process is the Four Points Bending Test. Naval registers and ISO standards give designers the rules for a proper dimensioning of the windows on a yacht and they determine the standard flexural strength value to be used in the calculations.

It’s also known that glass can be strengthened with chemical tempering and ISO 1288-3 allows us to prove the efficacy of such a process through a destructive test. A minimum of 10 strengthened specimens of the same thickness needs to be tested to determine the characteristic breaking load of the ply and consequently, the enhanced flexural strength value to be used in the calculations.

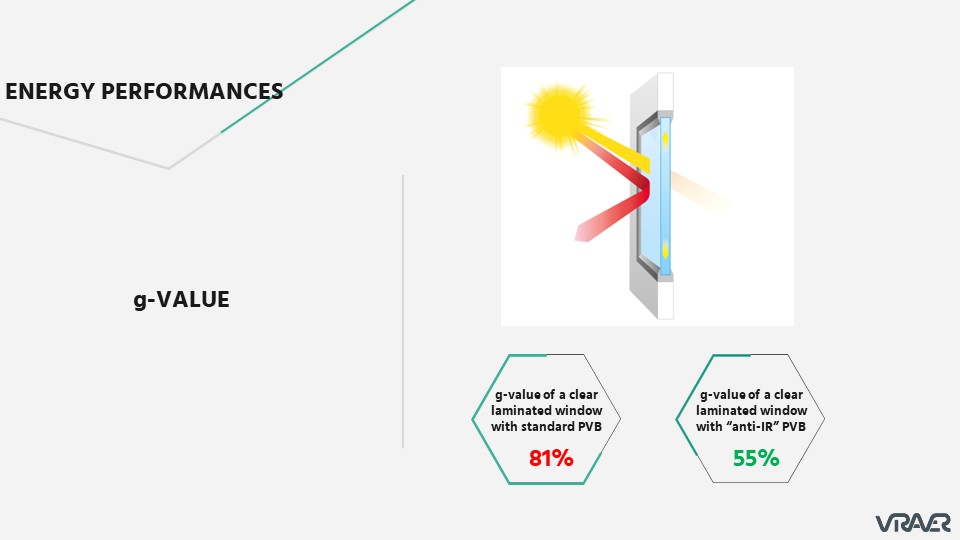

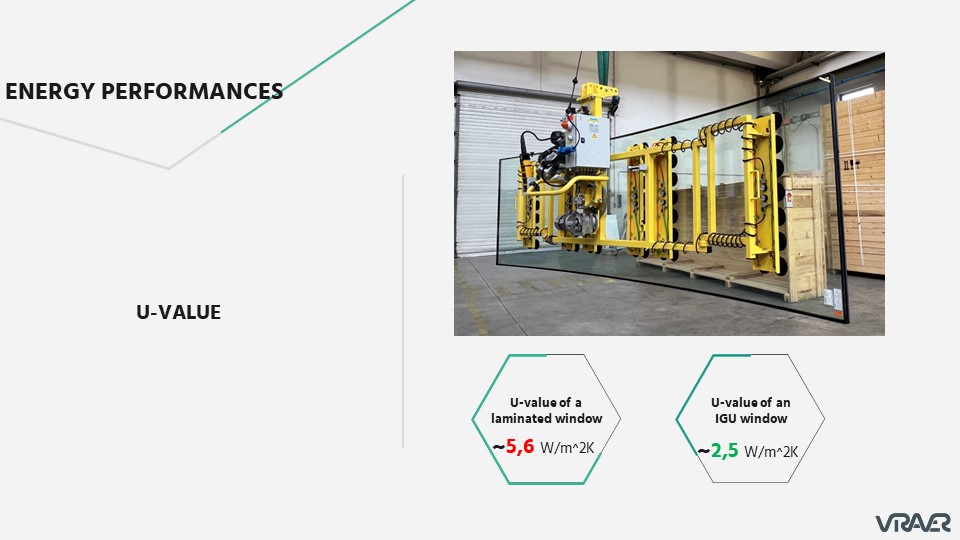

When energy performance of the glass is analyzed, or the glazing system, it’s all about g-Value and U-Value.

The g value can be expressed either as a percentage, or a decimal and it tells how well the glass transmits heat from the sun to the indoor environment. The lowest the value, the better the performance of the glass that will be taken into account in the dimensioning of the HVAC.

g value can be reduced by means of interlayers that can reflect/absorb infrared radiation.

It’s very important to consider that also the color of the glass is very effective in solar protection.

U-value is the measure of the insulating capacity of the glass and expresses the heat loss through the window per square meter for one degree difference between the internal and external temperature (W/m^2K).

The lower the U-value, the less heat is lost and the more insulation the material provides.

The best way to reduce the U-value is by means of a cavity between two glasses, which is called IGU: “Insulated Glass Unit”

Weight reduction is achieved with weight reduction which is a result of advanced technology which by consequence means the creation of high preforming glass. Energy saving is part of a cycle, and it is achieved via means of more comfort and recycling.

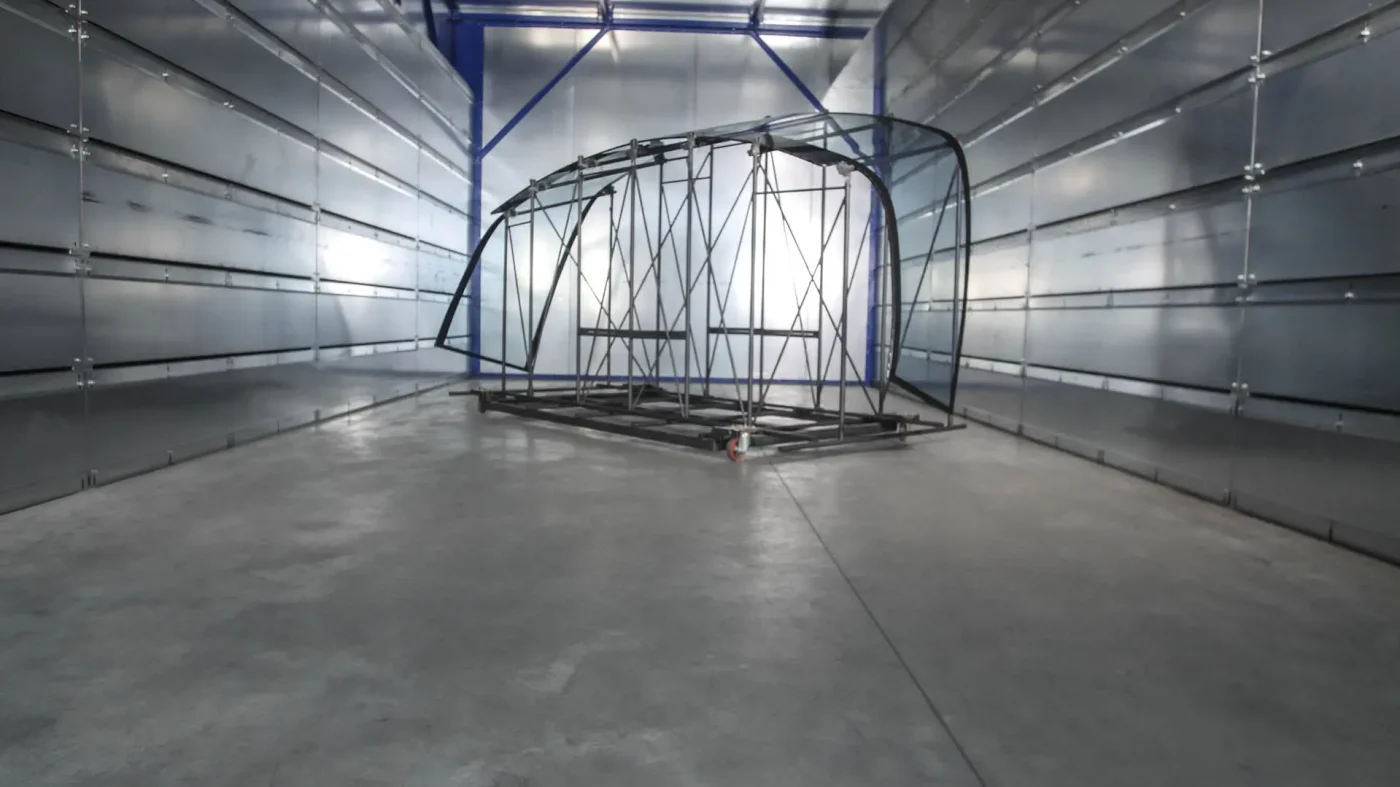

Viraver sketches, designs and manufactures flat and curved, monolithic and laminated safety glass with applications and special solutions tailored for the most iconic Superyacht, and works with the shipyards and designers, with an inspiring open-minded approach.